Custom made bags and pouches to order.

Click here to check out our gallery.

Bags & Pouches

2 Way Radio Pouch

Custom Made Knife Pouch

Ostrich Leather Shearers Comb Pouch

Personalised Laptop Bag

3 - 4

<

>

BACK TO SITE

High quality, custom Bronc Saddles.

Click here to check out our gallery.

Bronc Saddles

2 - 2

<

>

BACK TO SITE

High quality, custom Stock Western Fender Saddle.

Click here to check out our gallery.

Stock Western Fender Saddle

3 - 16

<

>

BACK TO SITE

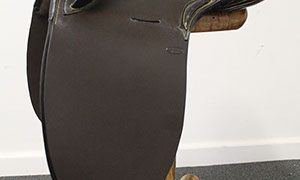

High quality, custom Traditional Saddles.

Click here to check out our gallery.

Traditional Saddles

17 - 17

<

>

BACK TO SITE

BRADY'S SADDLERY

MASTER SADDLERS SINCE 1974

Saddle-making has been in the Brady family since Tom Brady made his first saddle as a young man in the 1940's. Since then Brady saddles have been ridden in and owned by movies stars, World Bronc Rider Champions, Warwick Gold Cup winners and many hundreds more. Tom's son Bernie is now working on saddle number 1000.

Bernie Brady's saddles have twice been in the Sydney show " Showcase of Excellence" in 2000, and 2007, as well as winning first prize at the Sydney Royal in 2000, 2001, 2002 and 2007.

"No brand names, no model numbers. Each Brady saddle has been individually handcrafted to suit the horseman's needs" says Bernie. During the 70's and 80's the saddlery was on the road travelling from South Australia to Queensland and everywhere in between.

Tom and Bernie, they are able to put their horsemanship skills to use in the building of a saddle, aiming to get the best fit and optimal performance out of each saddle.

MESSAGE FROM BERNIE

Message From Bernie

I would like to tell you a little about myself & how I learnt my craftsmanship skills. My mother was incredibly talented with so many handicraft skills, from cake decorating to fine needlecraft & knitting and may other crafts.

It was my dad who taught me my saddle making skills, which he learnt from bespoke saddler, Bob Thurlow. I also soaked up as much knowledge as I could from many visits to Master Saddler Warren Newcombe’s shop, when he worked in Walcha. This also included doing work experience with him while I was at school. I made my first saddle at 13 which I still have today, and it is a good as the day I made it.

The rest of my knowledge has come from years of studying saddles and many hours in the saddle, while growing up and during my first 5 years of work as a stockman. I also competed in pony club and horse sporting events through to campdrafting and polo cross.

Dad & I worked on the land and during the 60’s made saddles and strapping/leatherwork in our spare time to fill orders that were coming in from locals.

In the 70’s local saddler, Warren Newcombe, left Walcha for Grafton so we decided to open up a saddlery in town in October 1974. Orders came in thick & fast and to get our name out to the wider market, we travelled to rodeos and horse events from Townsville to Adelaide and many place in-between, with our mobile shop.

I specialise primarily in traditional stock saddles and stock western for customers who use them for general stock work through to campdrafting & polocrosse. I have made western saddles for horse trainers and my Bronc saddles for competition riders competing at rodeos in most states in Australia. Ray Herman won SEVEN AUSTRALIAN & TWO WORLD TITLES in the 1980’s in a saddle that I specially made for him. Allan Powell won the 2012 Central Qld Saddle Bronc title and the 2013 PRCA

Rookie Title in a Brady’s Bronc Saddle.Walcha’s Carl Green won the 2013 ABCRA Australian Title also in a Brady Bronc Saddle.

I am a traditional saddle-maker, who still hand cuts and hand sews (not like larger saddle manufacturers, who use mechanical cutting tools). For a traditional counter- lined saddle the time from start to finish is on average 80hrs. And each saddle is custom made for the customer which is so important. It has to be comfortable for both the horse and the rider. It is a true art form and no two saddles are the same. I hand cut the pattern out for the saddle and then commence building from the seat up. This process has several stages, including hand-sewing, tacking & wetting the leather, as it is worked at different temperature and moisture and oil contents for different applications. Some on my saddles have extensive “tooling” (which adds to the completion time) where I carve special designs into the leather to create an even more unique and personalised saddle.

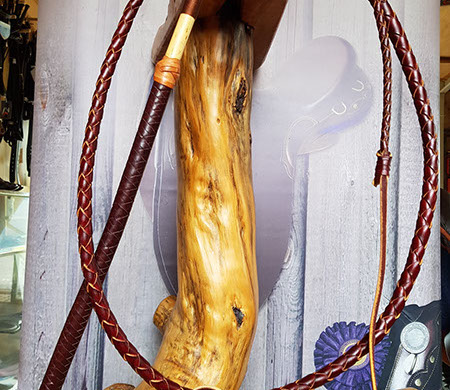

Since my dad passed away in 2016, I have taken up plaiting whips which is another craft that I enjoy and it is stimulating to create new styles and learn different techniques. Since relocating the saddlery to my new workshop at home it has given me the chance to re-energise my creativity and produce new styles and products. Call into our new “Leather Studio” at rear of 105e Hill Street Walcha, or give me a call on 0429772004.

Bernie B

BACK TO SITE

Authentic leather and riding crops made to order.

Click here to check out our gallery.

Riding Crops & Whips

16-Strand 2-Tone Roo Hide Whip

12-Strand 2-Tone Trophy Whip

12 Strand Riding Crop with Brass Knob

4 Strand Latigo Whip with 8-Strand Kangaroo Half-Plait Handle

12-Strand 2-Tone with ½-Plait Handle

8 stand with Initials Inlaid

Trophy Riding Crop with Silver Tip

Trophy Whip Mounted

5 - 8

<

>

BACK TO SITE

Specialty items requested by our customers.

Click here to check out our gallery.

Specialty Items

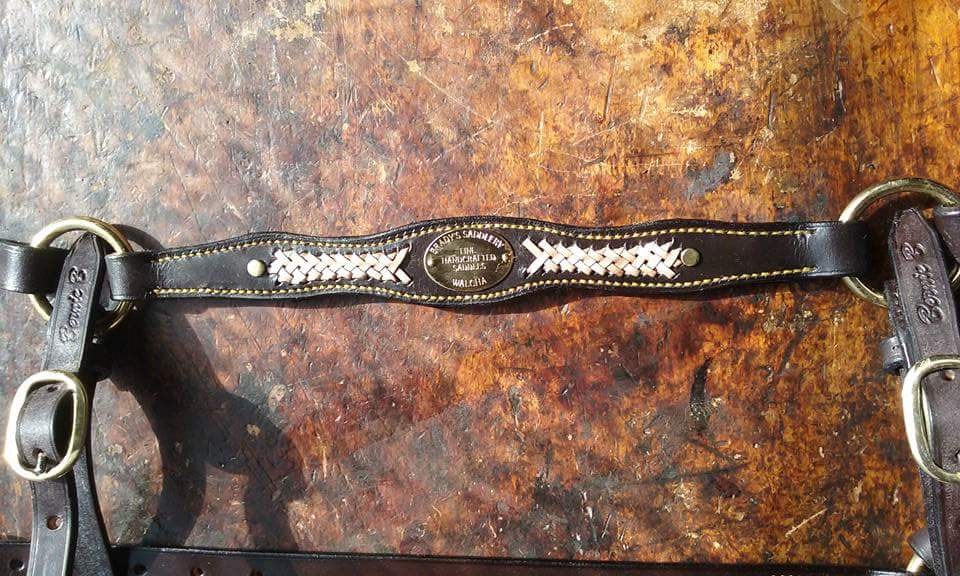

Close-Up of Breastplate with Plait Inlay

Ladies Belt

Horse Hair Plaited Into Belt

Ladies Belt 2

Leather Breastplate

Made to Order Brady's Belts

Notebook Covers

Bullwhip Hatband

3 - 8

<

>

BACK TO SITE

High quality, custom Western Saddles.

Click here to check out our gallery.

Western Saddles

1 - 1

<

>

BACK TO SITE

Our selection of our award winning saddles.

Click here to check out our gallery.

Trophy Saddles

15 - 15

<

>

BACK TO SITE

<

>

WHAT OUR CUSTOMERS SAY

CONTACT US

MAKING OF MUSEUM SADDLE

Step 1:

Timber tree.

Step 2:

Pailting Crupper D

Step 3:

Tree webbed & belly & candlebind prepared.

Step 4:

Flap cutout and kneepad handstiched into place.

Step 5:

Imitation thighpad in place. 9 stiches to the inch on outside sew.

Step 6:

Flap completed.

Step 7:

Back facing completed.

Step 8:

Top on saddle and flaps on.

Step 9:

Panel completed including leather lining instead of serge.

Step 10:

Progress shot prior to panel being fillted.

Step 11:

Panel stiched in.

Step 12:

Saddle completed.

Angle 1

Angle 2

Angle 3

Close up 1

Close up 2

Close up 3

Close up 4

Angle 5

Angle 6

Angle 7

Angle 8

Angle 9

Close up 5

Close up 6

Close up 7

Close up 8

Close up 9

<

>

BACK TO SITE

From first contact with you I was happy. You spent time talking with me about me needs and acknowledged the significance for me in buying my first Hand- made saddle. The work you then put into creating a saddle that will give me a lifetime of riding pleasure has blown me away.

I wanted a saddle I could use for showing, campdrafting and bush bashing and you “delivered”. The quality of leather, the detail in the hand stitching, the deep seat, narrow waist, saddle flaps to fit my length of leg perfectly, plus a bit of “bling”. This saddle gives me the close contact that I was looking for.

I am currently bringing my three year old back into work after two months spell and even after the first ride I could feel how much better her responses are to my legs and seat. I look forward to many more hours in this saddle, “It’s better to ride in a Brady’s Saddle than wish you did.

Sarah Wooding

Victoria

Thank you for the wonderful leather belts we purchase from you they are amazing and we value you making these. To give a belt as a gift with your Saddlery Emblem, on it has a value as it is hand made, and I feel as if the gift has a meaning because it is so well made.

Also this this keeps Australia going, with giving Australian products.

Thank you Bernie well done for what you do.

BEV BETTS

WALCHA NSW, 2354

Thank you to Brady’s Saddlery.

Over the past 20 years I have tried many saddles in a hope to get enough confident to be able to ride horses without fear.

After stumbling upon Brady’s Saddles, I can finally enjoy my home bred ponies. “A quality well build saddle can change your world”

Thank you Bernie

Jen Sansom

BERNIE CUTTING OUT WHIP ▶

BACK TO SITE

BERNIE PLATTING WHIP ▶

BACK TO SITE

BRADY'S SADDLERY

PROJECTS